Thread specifications: Metric M thread.

Product material: Parts C and E are made of nickel-plated brass, D is made of stainless steel, B and F are made of aging-resistant silicone rubber, and A is made of tetrafluoroethylene.

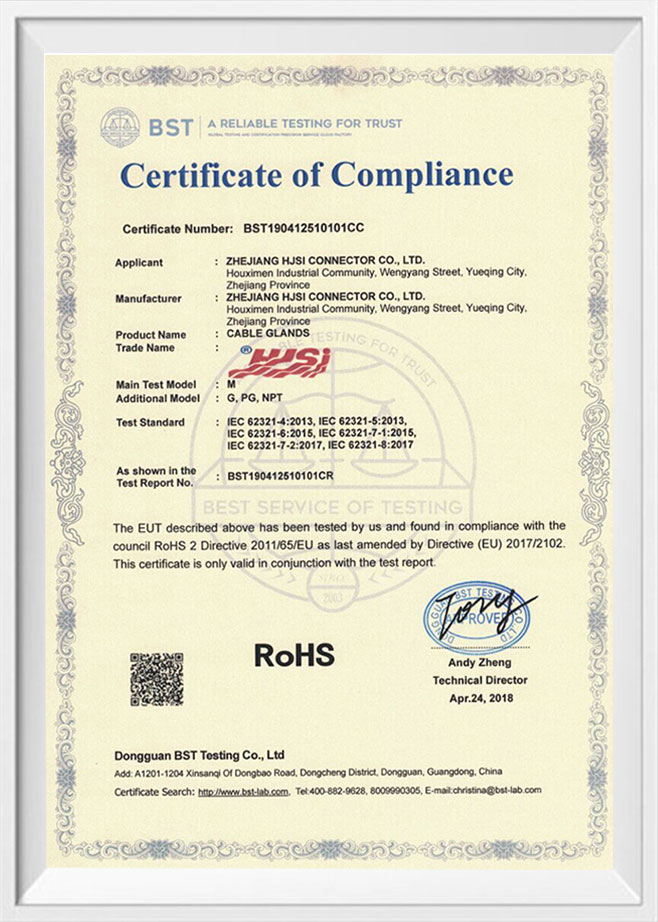

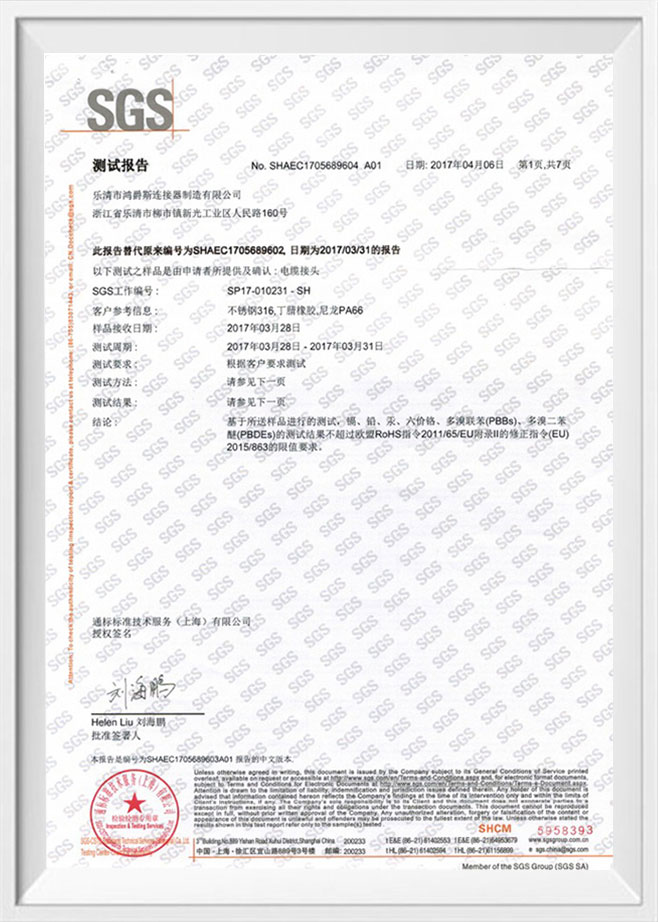

Product certification: CE, EX, ROHS.

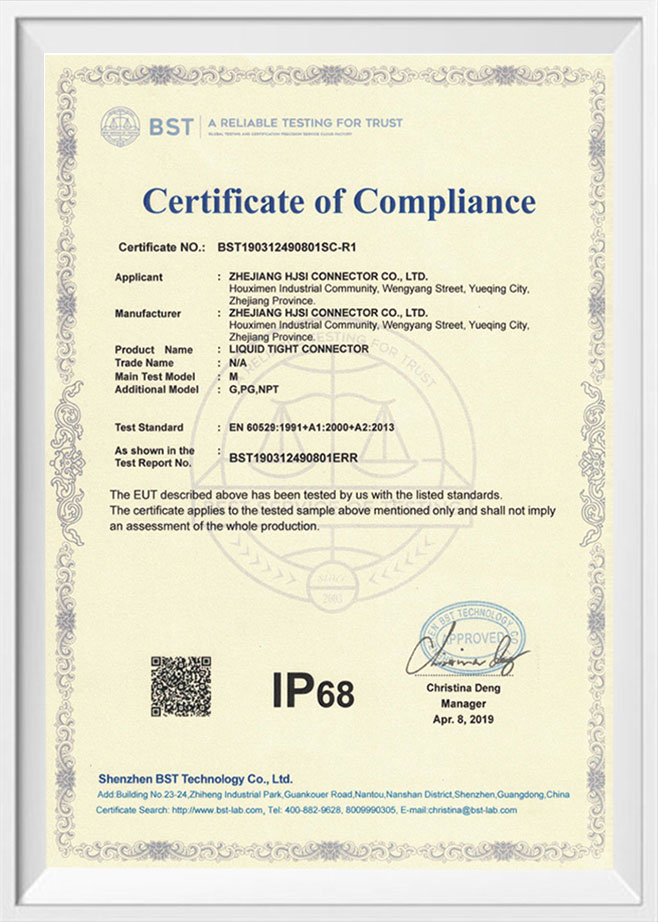

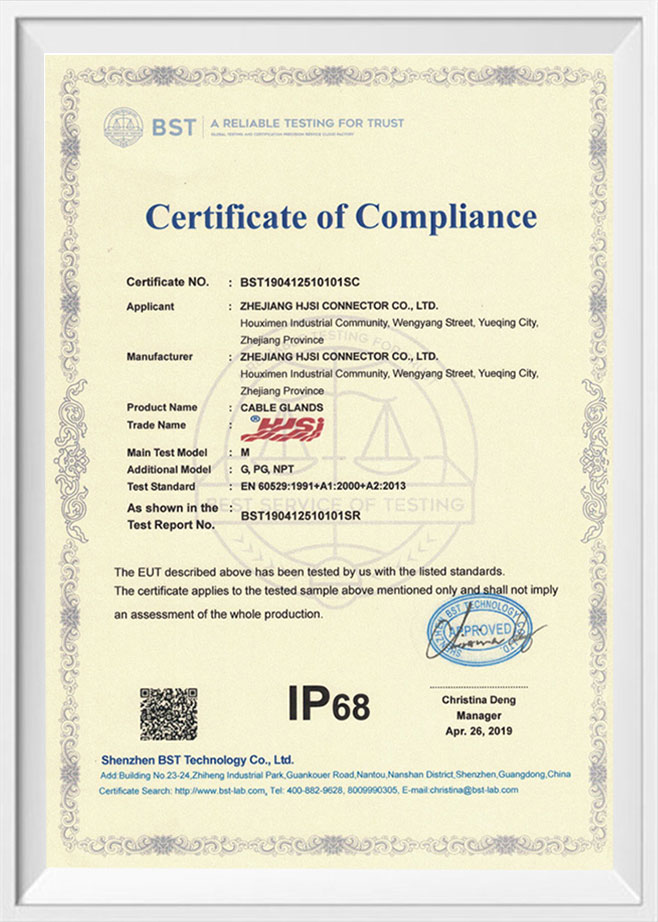

Protection level: Within the specified bayonet range, use a waterproof 0-ring and clamping ring to tighten the tightening head, reaching IP68.

Operating temperature: 40°C to 150°CFlame retardant grade: 94V-0 (GB/T2408-2008).

Product features:

1. Use a PTFE gasket to reduce friction between the rubber surface and the metal surface and extend service life.

2. Using spring shielding, the shielding contact surface is large and the installation efficiency is high.

3. The internal rubber is made of silicone, which allows the product to operate normally in extremely cold weather.

4. This product achieves contact sealing between the clamping ring and the cable surface, which can effectively prevent the cable from entering the motor or controller if it is damaged.

Body and Nut Optional: Brass with nickel plating, Stainless steel.

Clawing: PA6 with flame retardant (UL File No: E240925) Sealing and Washer: TPE.

Contact Spring: Stainless steel.

IP rating: IP68 to EN60529.

Ambient Temperature: -40~C to 150°C.

Entry Thread: Metric, PG, NPT, G.

Thread Length: Standard, Longer available as per demand.

Strain Relief: Acc. to EN 50262.

Accessory: Gland comes with a locknut, inserting sealing, and gasket.

Approvals: CE, RoHS, REACH.

Key Features of HJSI EMC Cable Gland:

Superior Material Construction:

The HJSI EMC Cable Gland features a combination of high-quality materials designed for optimal performance and longevity:

Parts C and E: Made of nickel-plated brass, providing excellent corrosion resistance.

Part D: Constructed from stainless steel, offering high strength and durability.

Parts B and F: Manufactured with aging-resistant silicone rubber, ensuring a long service life.

Part A: Constructed from tetrafluoroethylene (PTFE), offering low friction and superior sealing properties.

IP68 Protection:

The HJSI EMC Cable Gland meets the IP68 protection rating as per EN60529, ensuring complete dust-tight protection and resistance to prolonged submersion in water. This makes it ideal for use in demanding environments where exposure to moisture, dust, and other contaminants is a concern.

Wide Operating Temperature Range:

With an operating temperature range from -40°C to 150°C, the HJSI EMC Cable Gland is designed to function effectively in both extreme cold and high-temperature environments. Its flame retardant grade of 94V-0 (GB/T2408-2008) also ensures it will not contribute to fire hazards in the event of a fire.

EMC Shielding for Enhanced Performance:

Featuring spring shielding with a large contact surface, this cable gland ensures high shielding efficiency, reducing electromagnetic interference (EMI) and enhancing the overall performance of your electrical systems. This feature is particularly valuable in applications that require electromagnetic compatibility (EMC), such as in sensitive electronic equipment or telecommunications systems.

PTFE Gasket for Reduced Friction:

The PTFE gasket used in the HJSI EMC Cable Gland minimizes friction between the rubber surface and metal components, reducing wear and extending the lifespan of the gland. This ensures that the product will remain functional over an extended period, even in high-stress environments.

Strain Relief Mechanism:

Designed in accordance with EN 50262, the gland incorporates a strain relief feature that ensures secure cable retention, preventing damage or loosening due to mechanical stress or movement. This makes it especially suitable for environments with high vibration or mechanical impacts.

Seal and Washer Made from TPE:

The sealing and washer components are made from TPE (Thermoplastic Elastomer), which provides excellent sealing properties and ensures a long-lasting, waterproof connection between the gland and cable.

Wide Range of Thread Options:

The HJSI EMC Cable Gland offers various thread types including Metric, PG, NPT, and G, with both standard and longer thread lengths available to meet specific installation requirements.

Applications of HJSI EMC Cable Gland:

Industrial Applications:

The HJSI EMC Cable Gland is perfect for industrial environments where dust, moisture, and mechanical stress are prevalent. It is commonly used in power plants, manufacturing facilities, and processing plants where durability and protection against harsh conditions are essential.

Telecommunication and Networking Systems:

Due to its EMC shielding properties, the HJSI EMC Cable Gland is ideal for telecommunications and data networking systems. It ensures that electromagnetic interference (EMI) is minimized, protecting sensitive equipment and data transmission.

Automotive and Electric Vehicles:

This cable gland is highly effective in automotive and electric vehicle applications, where vibration, temperature fluctuations, and the need for a secure, waterproof seal are critical factors in maintaining system integrity.

Marine and Offshore Equipment:

The IP68 rating and flame retardant materials make this cable gland perfect for use in marine and offshore environments, ensuring that electrical systems are protected against harsh elements like saltwater, moisture, and extreme weather conditions.

Solar Power Systems:

The HJSI EMC Cable Gland is well-suited for solar power systems, where protection against the elements and effective sealing of cables is essential to maintaining system efficiency and safety.

Control and Automation Systems:

In control and automation systems, the HJSI EMC Cable Gland helps protect cables from environmental contaminants while ensuring secure cable entry and reliable electrical performance.

English

English русский

русский عربى

عربى